Brass Forged Valves provider in Germany

Introduction

Since 2002, Shalibhadra International has been a trusted name in precision brass and metal components. With over two decades of expertise in OEM manufacturing, custom metal parts, and global exports, we have built a strong reputation for quality and reliability. In 2023, we formalized our legacy by incorporating as Shalibhadra International Private Limited.

Germany, a manufacturing and technical powerhouse, is known for its accuracy, robustness, and inventiveness. Every part utilized in its extensive industrial landscape is subject to this dedication to quality, and brass forged valves are no different. Reliable, high-performance brass forged valves are constantly in great demand, from intricate plumbing systems to complex industrial machines.However, why are “Brass Forged Valves Provider in Germany” such a vital search keyword for companies in this industry, and what precisely makes these valves so important. We are the best Brass Forged Valves Manufacturer.

Why Brass Forged Valves

Mechanical devices called brass forged valves are used to direct, control, or regulate the flow of fluids in a pipe system. The word “forged” refers to the valve body’s manufacturing technique, which shapes metal under great pressure to create a stronger and more resilient part. We are the best Brass Forged Valves Supplier.

Why Choose Shalibhadra International

- Unwavering Dedication to Quality: At Shalibhadra International, quality is the cornerstone of everything we do and is not only a catchphrase. Strict quality control procedures are followed throughout our manufacturing process, from the selection of raw materials to the last inspection. As a firm with certification, we guarantee that every brass forged valve that leaves our factory satisfies global requirements and operates faultlessly. To ensure their integrity, our goods go through extensive testing, including non-destructive and hydraulic tests.

- Modern production Facilities: We run our business out of a very sophisticated production facility that is furnished with sophisticated, semi-automated machinery. This enables us to fulfill orders of various sizes without sacrificing quality by maintaining accuracy, efficiency, and a vast production capacity.

- Forging expertise: We are aware of the subtleties involved in forging brass. The highest quality raw materials are used to make our valves, guaranteeing exceptional strength, longevity, and corrosion resistance all of which are important advantages of forged brass that you previously read about.

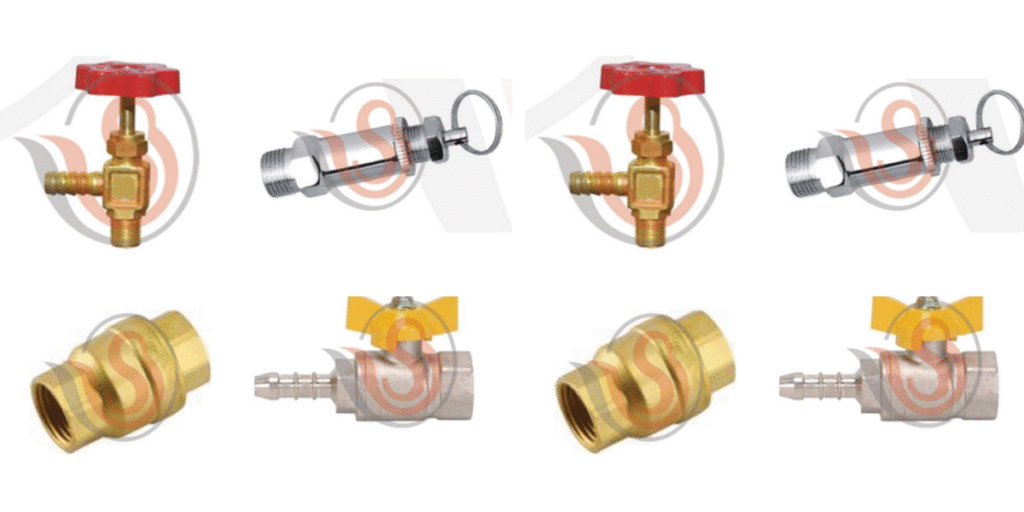

- Broad Selection of Brass Forged Valves: Shalibhadra International provides a wide range of products to meet the needs of different industrial and commercial applications, including compressor delivery valves, gas valve bodies, mini ball valves, non-return valves (horizontal or vertical spring type), quick release couplings, and safety valves. In order to satisfy your unique design and material needs, we can provide customisation alternatives.

- Global Export Capabilities: We are a seasoned exporter with a solid international product delivery network. We guarantee safe and timely delivery by air, sea, or road because we are aware of the logistical requirements of global trade.

- Customer-Centric Approach: Our group of extremely knowledgeable and experienced experts is committed to making sure that every client is completely satisfied. We pay attention to your needs, offer efficient after-sales care, and offer technical assistance. Our first goal is your success.

- Competitive Pricing: Our effective manufacturing procedures and strategic sourcing enable us to offer competitive pricing, offering exceptional value for your investment, without sacrificing quality.

Applications of Brass Forged Valves

- Plumbing & Water Systems: Forged brass valves are the foundation of water supply and distribution networks in both residential and commercial structures. Their longevity provides leak-free operation in both hot and cold water lines, and their non-toxic nature guarantees safe drinking water. Formed brass valves are essential to the effective operation of the complex heating, ventilation, and air conditioning (HVAC) systems found in contemporary German buildings.

- Automotive Industry: Germany is known for producing high-quality automobiles. Vehicles use forged brass parts, such as specialty valves, in many areas, but especially in the cooling, brake, and fuel systems. Vehicle performance and safety depend heavily on their capacity to tolerate high pressure and wear under harsh circumstances.

- Mechanical and Plant Engineering: Accurate fluid control is crucial in the huge world of industrial facilities and machinery. Pneumatic and hydraulic systems, processing facilities, and other pieces of equipment where dependable flow control is essential for both operational effectiveness and safety use forged brass valves.

- Energy Sector: Regulating the flow of different fluids and gasses is a constant in both conventional power plants and renewable energy installations. High-pressure and high-temperature qualities make forged brass valves indispensable in a variety of energy applications, such as those involving gas, oil, and steam.

- Chemical and Petrochemical Industries: Forged brass valves are used in chemical plants to handle less aggressive chemicals and in utility lines, where their sturdy design and leak-proof operation are highly prized. However, specialized materials are frequently used for highly corrosive substances.

- Agricultural Irrigation: To control water flow for irrigation systems in agricultural settings, withstand outdoor conditions, and guarantee effective water distribution, sturdy valves are required.

Specification Table of Brass Forged Valves

| Parameter | Specification |

|---|---|

| Material | Brass Forged Valves |

| Sizes Available | 1/4″ to 4″ (DN6 to DN100) |

| Pressure Rating | PN16, PN25, PN40 |

| Thread Standards | BSP, NPT, ISO, DIN, ANSI |

| Operating Temperature | -20°C to +120°C |

| Surface Finish | Natural Brass / Nickel-Plated / Chrome-Plated |

| End Connection | Threaded / Solder / Compression / Flanged |

| Handle Material | Steel / Aluminum / Plastic-Coated |

| Testing Standard | EN 12266-1, ISO 5208, API 598 |

| Manufacturing Standard | EN, DIN, JIS, ANSI |

| Warranty | 1 Year |

Advantages of Brass Forged Valves

- Outstanding Sturdiness and Power: The term “forged” in brass forged valves describes a production method in which brass is heated and then molded under extreme pressure. By removing internal flaws like porosity and air bubbles that are frequently present in cast substitutes, this method produces a thick, homogeneous grain structure. The outcome? valves that can tolerate greater pressures and temperatures, are noticeably stronger, and are more resilient to wear and tear. This improved durability results in longer operational lifespans and lower maintenance costs for German industries where dependability is crucial.

- Superior Corrosion Resistance: Compared to other metals like iron or certain steels, brass, an alloy of copper and zinc, has a natural exceptional resistance to corrosion. Because of this, brass forged valves are perfect for a variety of uses, such as those involving gas, water, and other chemicals. This resistance guarantees the integrity of the valve and stops leaks, which is crucial for efficiency and safety in humid conditions or systems that handle potentially corrosive fluids.

- Leak-Proof Performance: Extremely tight seals are made possible by the precise forging manufacturing process and the intrinsic qualities of brass. This reduces the possibility of leaks, which can result in expensive downtime, serious material loss, and environmental risks. It is not only desirable but also essential for critical German industrial applications to have a leak-proof system.

- Versatility in Applications: Brass forged valves are appropriate for a wide range of applications since they are available in a variety of designs, including ball, gate, check, and more. Their versatility makes them a flexible option for German engineering, ranging from plumbing for homes and businesses to complex industrial systems like water treatment, oil and gas, and HVAC.

- High-Temperature Resistance: High temperatures are used in a lot of German industrial processes. In contrast to some plastic substitutes that may distort, brass forged valves are ideal for these circumstances because they retain their structural soundness and functionality even when heated.

- Ease of Operation and Maintenance: These valves are often made for easy quarter-turn operation (for ball valves) or basic open/close mechanisms. Because of their durability, they require less maintenance, which saves money and time.

Types of Brass Forged Valves

1. Brass Ball Valves

- These valves use a spherical disc to control flow. They offer tight sealing and are ideal for quick shut-off applications.

Applications: Water supply systems, gas pipelines, HVAC units.

2. Brass Gate Valves

- These valves are used to start or stop the flow, not to regulate it. A wedge-shaped gate inside the valve rises or lowers to allow flow.

Applications: Oil refineries, irrigation, chemical plants.

3. Brass Check Valves

- Also known as non-return valves, they allow fluid to flow in only one direction, preventing backflow.

Applications: Water pumps, reverse osmosis systems, fire sprinkler lines.

4. Brass Globe Valves

- These valves are used to regulate flow in a pipeline. The flow is adjusted by the position of a movable disc.

Applications: Fuel systems, chemical feed systems, and water cooling.

5. Brass Angle Valves

- These valves are L-shaped and control flow from perpendicular connections, often used in plumbing systems.

Applications: Under-sink installations, toilets, water heaters.

6. Brass Pressure Reducing Valves

- These valves reduce incoming water or gas pressure to a manageable level.

Applications: Water distribution networks, gas regulators.

7. Brass Stop Valves

- These valves are used to isolate flow during maintenance or emergencies.

Applications: Domestic water lines, industrial plumbing.

Conclusion

Reliability, accuracy, and durability are key components of the German industrial landscape. Because of their inherent strength and exceptional performance qualities, brass forged valves are an essential part of innumerable applications in a wide range of industries. Shalibhadra International presents a strong option for companies in Germany looking for a supplier who is aware of these important requirements. We are the best Best Brass Forged Valves Provider.

We are well-positioned to be your reliable partner for all of your brass forged valve needs thanks to our vast experience, unwavering dedication to quality, wide choice of products, and capacity for custom solutions. We extend an invitation to German enterprises to discover the Shalibhadra International distinction, where performance is always of utmost importance and quality meets dependability.