Customized Components OEM Manufacturer

Introduction

Since 2002, Shalibhadra International has been a trusted name in precision brass and metal components. With over two decades of expertise in OEM manufacturing, custom metal parts, and global exports, we have built a strong reputation for quality and reliability. In 2023, we formalized our legacy by incorporating as Shalibhadra International Private Limited.

Precision, dependability, and customisation are now essential in today’s quickly changing industrial environment. Globally, manufacturers are looking more and more for partners who can provide components that meet their exact standards. This is where Shalibhadra International excels as a reputable OEM manufacturer of customized components, providing innovative solutions that promote effectiveness, quality, and creativity.There is a universal need for robust, high-tolerance parts for anything from systems and refrigeration to automobiles and industrial machines. This article examines Shalibhadra International’s fundamental competencies and highlights the main arguments for why working with them is a wise choice for companies trying to improve their supply chain with accuracy, dependability, and quality. We are the best Customized Components OEM Supplier.

Understanding Customized Components OEM

Specialized parts created and produced to satisfy the unique needs of a customer’s equipment, system, or product are known as customized components. Customized solutions, as opposed to regular off-the-shelf components, enable companies to improve equipment longevity, minimize operational inefficiencies, and maximize performance. Precision-engineered components that meet specific operational requirements are becoming more and more necessary in industries like automotive, aerospace, electronics, industrial machinery, and renewable energy. A trustworthy OEM manufacturer like Shalibhadra International is essential in this situation. We are the best Customized Components OEM in GUJARAT.

Why Choose Shalibhadra International

- Uncompromising Commitment to Quality and Stability Shalibhadra International operates on a foundation of Total Quality Management hey begin with certified, premium raw materials and employ a blend of advanced automation and skilled craftsmanship. This, combined with their strong financial position and over legacy, translates into a dependable supply chain you can rely on for the long term, without fear of unexpected disruptions.

- Technical Partnership Approach Beyond manufacturing, Shalibhadra International positions itself as a technical partner to its clients. The company’s experienced engineers provide expert consultation on component selection, installation methods, and design-for-manufacturability insights . This collaborative approach helps clients avoid common pitfalls and optimize their products for performance and production efficiency.

- End-to-End Supply Chain Solutions The company offers comprehensive services as manufacturer, supplier, and exporter. Domestically, they supply across major Indian trade centers, including Delhi, Mumbai, Chennai, Kolkata, Bangalore, Ahmadabad, and Hyderabad. Internationally, they export products that comply with standards, ensuring global market compatibility.

- Reliability and Scalable Production With a robust production infrastructure capable of managing large-volume orders, Shalibhadra International serves as a dependable long-term supply partner for clients worldwide . The company maintains efficient supply chain and logistics operations that ensure timely delivery regardless of order size a critical consideration for industries where production schedules are tightly coordinated. This scalability is evidenced by the company’s production capacity of up to for certain product lines .

- Competitive Value Proposition While never compromising on quality, Shalibhadra International achieves cost-effectiveness through efficient large-scale manufacturing processes and lean management practices . The company’s pricing structure reflects its commitment to providing true value superior products that enhance the performance and longevity of client applications, ultimately reducing failure rates and saving money over the product lifecycle.

- Global Reach with Local Expertise Headquartered in Jamnagar, Gujarat, Shalibhadra International has cultivated a global client network while maintaining strong roots in India’s manufacturing ecosystem. The company serves markets across India including Delhi, Mumbai, Chennai, Kolkata, Bangalore, Ahmadabad, and Hyderabad while exporting to international clients who value precision-engineered components.

- Precision Engineering as Standard: We invest in state-of-the-art machinery and technology. This allows us to maintain exceptional dimensional accuracy and perfect threading on every single component. When you order from Shalibhadra International, you can be confident that the parts will fit perfectly every time, eliminating assembly-line headaches.

- Customization is Our Strength: Your design is unique, and your components should be too. We thrive on custom orders. Whether you need a specific thread size, an unusual length, a unique plating like or a completely custom-designed part, our engineering team can manufacture it for you efficiently and cost-effectively.

- Cost-Effective Solutions: Operating from Gujarat, a competitive manufacturing hub, Shalibhadra offers significant cost efficiencies without sacrificing material integrity. Their pricing structure is designed to be advantageous for bulk orders, providing scalable value that supports your project’s budget and profitability goals.

Applications of Customized Components OEM

1. Automotive Industry

- In the automotive sector, performance and precision are non-negotiable. Customized components such as precision gears, engine parts, and transmission components are critical to ensuring smooth operation and longevity of vehicles. Shalibhadra International provides automotive OEMs with high-precision components that meet global standards.

2. Electronics and Electrical Equipment

- Modern electronics demand highly specialized components that can handle complex circuits and high voltage applications. Customized connectors, housings, and mounting solutions from Shalibhadra International ensure reliability, safety, and optimal performance in electronic devices.

3. Machinery and Industrial Equipment

- Heavy machinery, manufacturing units, and processing plants rely on components that are durable and precisely engineered. Shalibhadra International’s customized industrial components help in maintaining high productivity levels, reducing machine downtime, and extending equipment life.

4. Aerospace and Defense

- The aerospace and defense sector requires components that meet strict tolerances and withstand extreme conditions. From precision machined parts to specialized fittings, Shalibhadra International manufactures components that comply with stringent industry standards.

5. Renewable Energy Sector

- The growing renewable energy sector relies on durable and efficient components for solar panels, wind turbines, and other green energy solutions. Customized components from Shalibhadra International ensure maximum efficiency and longevity, supporting sustainable energy initiatives.

6. Industrial Machinery

- Industrial machinery requires robust and durable components to handle high loads and continuous operation. Our components are designed to withstand extreme conditions, ensuring machinery reliability and reducing maintenance costs. Applications include conveyor systems, hydraulic machines, pumps, and compressors.

7. Consumer Goods

- Even everyday consumer products require customized components for efficiency, durability, and aesthetics. Shalibhadra International provides solutions for appliances, gadgets, and home automation devices, ensuring products perform flawlessly and meet consumer expectations.

Table of Specifications Customized Components OEM

| Specification | Details / Features |

|---|---|

| Material | Customized Components OEM |

| Product Type | Stainless Steel, Aluminum, Brass, Plastic, Composite Materials |

| Manufacturing Process | CNC Machining, Injection Molding, Casting, Fabrication, Assembly |

| Customization Options | Size, Shape, Color, Finish, Tolerance, Functionality |

| Tolerance Level | ±0.01 mm to ±0.1 mm (High Precision Manufacturing) |

| Surface Finish | Polished, Matte, Anodized, Coated, Powder Coated |

| Production Capacity | Small Batch, Large Volume, Prototype to Mass Production |

| Industry Application | Automotive, Electronics, Industrial Machinery, Aerospace, Consumer Products |

| Quality Standards | ISO Certified, RoHS Compliant, CE Certified |

| Lead Time | 2–6 Weeks (Depending on Order Size & Complexity) |

| OEM Services | Design Assistance, Prototype Development, Custom Branding |

| Packaging Options | Bulk, Individual Packaging, Customized Packaging |

| Additional Features | Cost-Effective, Durable, High-Performance, Reliable OEM Components |

Advantage of Customized Components OEM

- Superior Mechanical Strength: Customized Components OEM makes device casings lightweight, it frequently lacks the strength to endure the strain of frequent fastening and unfastening. A strong, long-lasting thread that can withstand high torque and stress without stripping or wearing out is offered by brass inserts.

- Machinability: Customized Components OEM is an extremely machinable material. For contemporary, small electronic devices, this makes it possible to create complex, accurate designs with tight tolerances. Additionally, this machinability lowers production costs and time.

- Versatility: These Customized Components OEM are available in a range of sizes, shapes, and knurling patterns, which are characterized by a textured exterior surface that offers a firm grip inside the plastic. They can be used for a variety of tasks because to their adaptability, such as mounting printed circuit boards and fastening terminals and connectors in consumer electronics and automotive systems.

- Design-Led Manufacturing: The process begins with a collaborative review of the product’s ultimate application and requirements. Engineers work with clients to determine optimal solutions, even creating prototypes for evaluation before finalizing designs.

- Material and Finish Flexibility: Whether a component needs to resist corrosion, conduct electricity efficiently, or bear specific loads, the right material and finish are selected. Options range from various brass alloys to specialized platings and coatings.

- Tailored Logistical Solutions: Customization extends to how products are delivered. Services include custom kitting, private labeling, and packaging tailored to the client’s supply chain needs, from bulk formats to retail-ready finished goods.

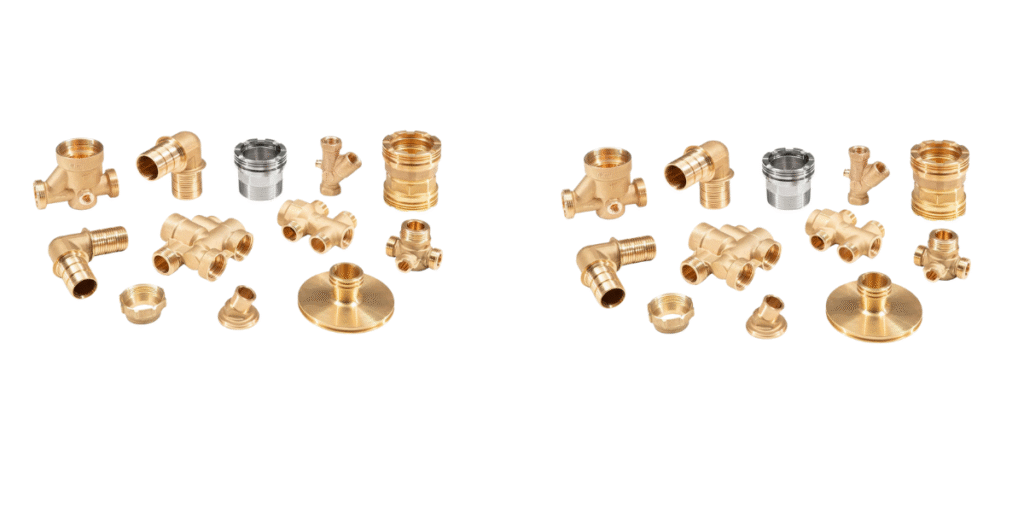

- Core Expertise and Specialization: Shalibhadra International has carved a niche in the precision manufacturing of brass components. Brass is favored in countless industries for its excellent machinability, corrosion resistance, electrical conductivity, and antimicrobial properties. The company’s extensive product portfolio includes.

- From Blueprint to Reality: Shalibhadra International utilizes precision automation machining like CNC to ensure products meet hyper-specific requirements for dimensions and tolerances. Every component is crafted from high-grade materials, with processes adhering to stringent quality checks.

- End-to-End Testing: Quality is not an afterthought. A reliable OEM employs both pre-production and post-production testing. This includes verifying material composition and conducting rigorous inspections to ensure every piece that leaves the facility is flawless.

- Economies of Scale and Expertise: By partnering with an OEM, you avoid the massive capital expenditure of purchasing specialized machinery, hiring skilled machinists, and maintaining a production facility. Shalibhadra International spreads these fixed costs across multiple clients, offering you competitive pricing without compromising on quality.

- Long-Term Value: While aftermarket parts may have a lower initial price, they often lead to higher costs through frequent replacements, downtime, and potential damage to other components. Investing in high-quality OEM parts from the start reduces total cost of ownership and enhances your product’s reliability.

Types of Customized Components OEM

1. Mechanical Components

- Mechanical components form the backbone of machinery and industrial equipment. Shalibhadra International manufactures.

2. Electrical Components

- Electrical components are crucial for the seamless functioning of modern machinery and electronic devices. Shalibhadra International offers.

3. Hydraulic and Pneumatic Components

- For industries relying on fluid power systems, Shalibhadra International produces customized hydraulic and pneumatic components, including.

4. Plastic and Polymer Components

- Plastic and polymer parts are essential for lightweight, corrosion-resistant applications. Shalibhadra International specializes in.

5. Metal Fabricated Components

- Metal fabricated parts are vital for structural integrity and heavy-duty applications. Shalibhadra International provides.

Conclusion

Businesses striving for success must collaborate with a reputable Customized Components OEM Manufacturer in a time when productivity, accuracy, and creativity are crucial. Shalibhadra International distinguishes itself as a reliable partner by delivering components that both meet and beyond customer expectations by fusing cutting-edge manufacturing capabilities, quality assurance, and customer-centric service. We are the best Customized Components OEM in Jamnagar.

Choosing Shalibhadra International gives businesses access to high-performance, bespoke parts that boost productivity, cut expenses, and foster industry innovation. Shalibhadra International continues to set the standard for quality in the production of customized components, whether they are used in industrial machinery, automotive, electronics, or medical applications.