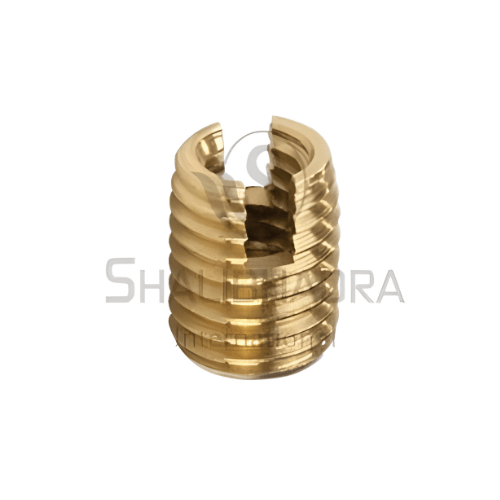

Brass Helicoil Insert - DBI-035

Brass Helicoil Insert

OEM Manufacturer | RoHS & ISO Certified

Helicoil Self Tapping Inserts re cylindrical metal bushings with internal and xternal threads. They are specially designed to cut their own threads as they are being driven into a drilled hole. Helicoil Self Tapping Inserts provide permanent wear-resistant threads in a wide range of materials, from tough to tap, high strength steels to brittle plastics. He thread cutting action is performed by the cutting slots on the self tapping insert. By tapping its own thread, the self tapping insert eliminates the need for pre-taped holes.

Brass Helicoil Inserts

General Information

Brand Name: Dutux

Product Type: Brass Helicoil Insert

Manufacturing Capability: Any size can be manufactured as per customer drawing or sample

Key Benefits

High-quality, permanent, and wear-resistant thread reinforcement

Easy to install and suitable for thread re-usability

Protects expensive base materials from thread damage

Improves load distribution and increases joint strength

Wide range of styles to suit almost every industrial application

Material Specifications

Free Cutting Brass IS 319 Type (I)

Free Cutting Brass as per BS 249 Type (I)

Standard grade: CuZn37Pb3 (Equivalent to BS 2874)

Optional grades available: CZ 121, CZ 131, C3604, CDA 360, DTD 627

High-grade free-cutting brass for excellent machinability

Custom brass material composition available on request

Thread Types Available

ISO Metric (MM Threads)

BA Threads

BSW Threads (Inches)

UNC, UNF, UNEF & NPT Threads

BSP & BSPT (Parallel & Taper Threads)

Any special thread as per customer specification

Finishing & Coating Options

Natural Finish

Golden Finish

Silver Finish

Nickel Plated

Chrome Plated

Tin Plated

Any special coating as per customer requirement

Packing Details

Bag Packaging

Box Packing

Inner Plastic Packing

Carton Packaging

Wooden Carton Packing

Special Features

Threads manufactured as per International Go & Not Go Gauge Standards

Provides strong, durable internal threads in soft or lightweight materials

Maintains precise inner diameter (ID) tolerance after installation

Prevents thread wear, stripping, and deformation during repeated assembly

Designed for long service life and consistent performance

Applications / Usage

Plastic Industries

Furniture Industry

Electronic Industry

Automobile Industry

Engineering plastic and light metal assemblies

Commercial Details

MOQ: 1000 Pieces

Lead Time: 3 Working Days

Price Terms Available:

EX-Work

FOB – Free On Board

C&F – Cost and Freight

CIF – Cost, Insurance & Freight