Brass Electronic Moulding Insert Gujarat

Introduction

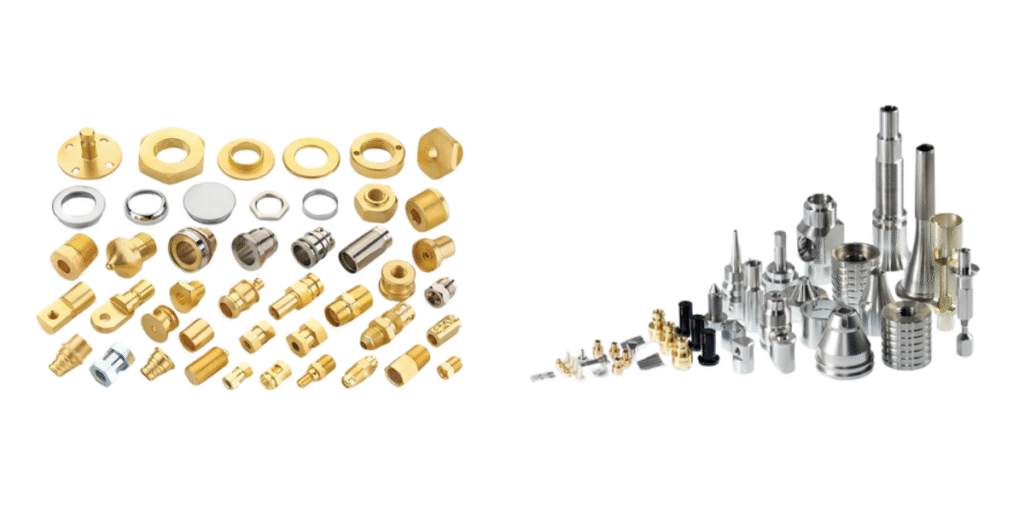

Since 2002, Shalibhadra International has been a trusted name in precision brass and metal components. With over two decades of expertise in OEM manufacturing, custom metal parts, and global exports, we have built a strong reputation for quality and reliability. In 2023, we formalized our legacy by incorporating as Shalibhadra International Private Limited.

Every single part, no matter how tiny, is essential in the intricate world of electronics. To guarantee performance and longevity, every component from the complex circuits on a motherboard to the device’s casing must function in unison electronic molding inserts are one of these crucial components. Despite their seemingly insignificant appearance, these inserts are essential to the production of contemporary electronics, particularly for plastic parts.You’ve come to the correct spot if you’re in Gujarat and trying to find a trustworthy supplier of Electronic Moulding Inserts. This post will define these inserts, discuss their importance in electronics, and highlight why Shalibhadra International is the best option for your requirements. We are the best Brass Electronic Moulding Insert Manufacturer.

What is a Brass Electronic Moulding Insert

A brass electronic molding insert is essentially a small, threaded metal fastener that is intended to be inserted into a plastic component. Consider the situation where you have to screw something into a plastic container. Direct screwing into plastic can result in weak connections, stripped threads, and cracking. This issue is resolved by a insert, which creates a sturdy, long-lasting, and reusable threaded hole.

Prior to the injection of plastic, these inserts are inserted into the mold. The insert is firmly locked in place as the hot, molten plastic surrounds it as it pours into the mold. This produces a product that has a strong metal thread integrated into the plastic, ready to be secured with a bolt or screw. We are the best Brass Electronic Moulding Insert Supplier.

Why Choose Shalibhadra International

- Decades of Experience: We have established a solid basis in the production and distribution of a broad variety of brass goods since our founding in Because of our experience, we are aware of the subtleties of threading, material grades, and production procedures needed to create high-quality electronic components.

- Unwavering Quality Control: At Shalibhadra International, quality is a fundamental value rather than merely a catchphrase. We adhere to a strict quality control procedure and employ premium raw materials. Each insert is examined to ensure that it satisfies national and international requirements for threading and dimensional accuracy.

- Modern production: We can produce accurate, reliable, and superior inserts in large quantities thanks to our state-of-the-art production plant in Jamnagar, Gujarat, which is furnished with cutting-edge gear. This technology, along with the knowledge of our knowledgeable staff, guarantees that you will always get a product that meets your exact requirements.

- Customization Potential: We recognize that each project is different. Whether you have a special material grade, a unique knurling pattern, or a non-standard size, our staff works directly with you to understand your needs. Our specialty is offering specially designed solutions that are ideal for your use case.

- Broad Product Portfolio: Although we specialize in brass electronic molding inserts, we are also skilled in a variety of brass products. Because of our adaptability, we can handle many of your brass component needs in one place.

- Precision and Customization: We are aware that no two situations are the same. We can provide custom brass electronic moulding inserts that meet your unique design and application requirements thanks to our state-of-the-art manufacturing facility and knowledgeable engineering staff. We can provide a solution that precisely matches your requirements, whether they involve a special size, thread type, or knurling pattern.

- Competitive Prices and On-Time Delivery: We think that quality should be within everyone’s means. We are able to provide cheap rates without sacrificing quality by streamlining our manufacturing processes. Additionally, we have a strong logistics network that guarantees your shipments are delivered consistently on time, assisting you in meeting your production deadlines.

- Global and Local Expertise: We have a significant presence in international markets in addition to our local industrial hub in Jamnagar, Gujarat, where we are situated. We are able to achieve the highest quality and design requirements because of our global exposure, which also provides us a distinct perspective.

Applications of Brass Electronic Moulding Inserts

Consumer Electronics

- Brass inserts are used in devices like smartphones, laptops, tablets, and home appliances. They help in creating strong internal connections and support electronic assemblies.

Automotive Industry

- Modern vehicles require multiple electronic components, such as sensors, switches, and control modules. Brass inserts ensure that these components are securely fixed and maintain proper electrical connections.

Industrial Equipment

- Machinery and equipment often use brass inserts in electronic panels and control units for durability under high stress and temperature variations.

Medical Devices

- Medical electronic equipment requires precision and reliability. Brass moulding inserts are widely used in devices like diagnostic machines, sensors, and other electronic instruments.

Telecommunication Equipment

- Brass inserts are also used in routers, switches, and other communication devices, providing stability and reliability to the electronic assemblies.

Table of Specifications Brass Electronic Moulding Inserts

| Specification Parameter | Details |

|---|---|

| Material | Brass Electronic Moulding Inserts |

| Diameter Range | 2 mm – 20 mm |

| Length Range | 5 mm – 50 mm |

| Thread Type | Metric/Imperial, Customized |

| Surface Finish | Polished / Nickel Plated / Custom Finish |

| Tolerance | ±0.01 mm |

| Hardness | 70 – 85 HB |

| Electrical Conductivity | 15 – 20 MS/m |

| Applications | Electronics, Automotive, Medical, Industrial |

| Packaging | Customized packaging as per client demand |

Benefits of Brass Electronic Moulding Inserts

- Outstanding Electrical Conductivity: Brass has exceptional electrical conductivity. For electronic applications where the insert might be a grounding point or a component of a circuit, this feature is non-negotiable. By ensuring a dependable and efficient current flow, brass lowers energy loss and improves the device’s overall performance.

- Resistance to Corrosion: Electronic equipment is frequently subjected to a range of environmental factors, such as chemicals and moisture. Because brass is inherently resistant to rust and corrosion, the insert won’t deteriorate with time. This durability guarantees that, even in challenging conditions, the connection’s integrity is preserved.

- Conductivity and Thermal Stability: Heat is produced by electronics. Because of its high thermal conductivity, brass can efficiently dissipate heat away from important parts, avoiding overheating and possible damage. By preventing problems like expansion or contraction that could cause failure, this thermal stability aids in maintaining the part’s structural integrity.

- Superior Mechanical Strength: Although plastic makes device casings lightweight, it frequently lacks the strength to endure the strain of frequent fastening and unfastening. A strong, long-lasting thread that can withstand high torque and stress without stripping or wearing out is offered by brass inserts.

- Machinability: Brass is an extremely machinable material. For contemporary, small electronic devices, this makes it possible to create complex, accurate designs with tight tolerances. Additionally, this machinability lowers production costs and time.

- Versatility: These inserts are available in a range of sizes, shapes, and knurling patterns, which are characterized by a textured exterior surface that offers a firm grip inside the plastic. They can be used for a variety of tasks because to their adaptability, such as mounting printed circuit boards and fastening terminals and connectors in consumer electronics and automotive systems.

Types of Brass Electronic Moulding Inserts

1. Threaded Brass Inserts

- These inserts have internal threads that allow secure fastening in plastic or polymer parts. They are widely used in consumer electronics, automotive components, and electrical appliances.

2. Knurled Brass Inserts

- Knurled inserts have ridges on their outer surface, providing a tight grip in the moulded plastic. This design ensures stability and prevents rotation or loosening under stress.

3. Press-Fit Brass Inserts

- These inserts are designed to be pressed directly into a plastic component. They create a strong friction fit without the need for adhesives or additional tools, making assembly faster and easier.

4. Heat-Set Brass Inserts

- Heat-set inserts are installed by heating the brass insert and pressing it into the plastic. As the plastic cools, it solidifies around the insert, creating a strong and permanent connection.

5. Customized Brass Inserts

- Shalibhadra International also provides customized brass electronic moulding inserts tailored to your specific designs and technical requirements. This flexibility ensures that our clients get the perfect solution for their manufacturing needs.

Conclusion

The smallest things can have the greatest impact in the cutthroat world of manufacturing. A product’s total durability, wear resistance, and connection strength are frequently determined by a single part: the brass electronic molding insert. Selecting the best supplier for these essential components has a significant impact on Gujarati enterprises’ bottom lines and brand reputation. We are the best Brass Electronic Moulding Insert Exporter.

Shalibhadra International is prepared to serve as that collaborator. Our dedication to excellence, accuracy, and client happiness guarantees that when you work with us, you’re receiving more than just a part—you’re getting a performance guarantee. Allow us to supply the solid connections that prolong the life of your products.