Brass Terminal Block Manufacturers

Introduction

Since 2002, Shalibhadra International has been a trusted name in precision brass and metal components. With over two decades of expertise in OEM manufacturing, custom metal parts, and global exports, we have built a strong reputation for quality and reliability. In 2023, we formalized our legacy by incorporating as Shalibhadra International Private Limited.

The two most crucial elements of contemporary electrical and electronic systems are dependability and safety. Every connection needs to be safe, whether it’s a big industrial installation or a tiny home panel. The brass terminal block is one such crucial element that guarantees secure wiring and steady power delivery. Brass has emerged as the most reliable material for electrical connections because to its strength, resistance to corrosion, and superior conductivity. We are the best Brass Terminal Block Supplier.

The need for top-notch Brass Terminal Block Manufacturers has grown along with the expansion of international industries. These days, businesses are looking for long-lasting, precisely crafted brass parts that enable long-term performance and meet international standards. This article will discuss the significance of brass terminal blocks, their main varieties, their uses, and why Shalibhadra International is a top manufacturer and supplier in this industry.

What Is a Brass Terminal Block

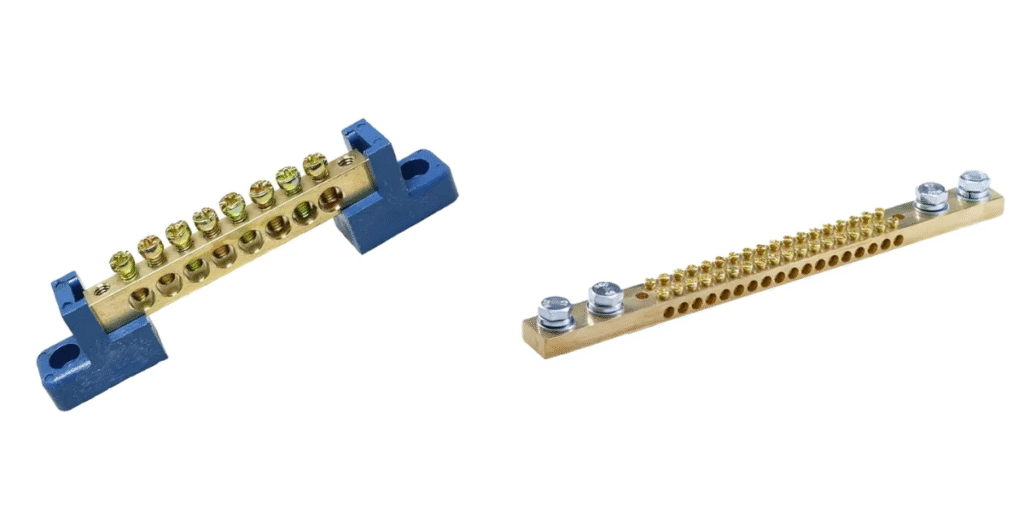

An electrical connector that firmly connects two or more wires is called a brass terminal block. It prevents overheating, loose connections, and short circuits while enabling the safe transfer of electricity from one location to another. While the conducting component, the connector, is made of premium brass, the base of the terminal block is frequently composed of insulating materials like ceramic or plastic. We are the best Brass Terminal Block Exporter.

Why Choose Shalibhadra International

- Uncompromising Quality Standards We maintain rigorous quality control processes that exceed industry standards, ensuring that every terminal block we produce delivers consistent performance and reliability. Our commitment to quality is evident in our detailed inspection protocols and our use of premium materials that come with material test certificates upon request.

- Technical Expertise and Innovation With years of specialized experience in brass component manufacturing, our technical team possesses deep knowledge of electrical connectivity requirements across industries. We don’t just manufacture components we provide solutions optimized for your specific applications and challenges.

- Comprehensive Customization Capabilities Unlike suppliers with limited product ranges, we offer extensive customization options to meet your exact specifications. From unique thread patterns to special mounting configurations, we work closely with our clients to develop terminal blocks that perfectly match their design requirements.

- Competitive Pricing and Value By optimizing our manufacturing processes and maintaining efficient operations, we deliver high-quality products at competitive prices without compromising on material quality or workmanship. We believe that excellence in electrical components should be accessible, and we strive to provide outstanding value to all our clients.

- Reliable Delivery and Customer Support We understand the importance of supply chain reliability in today’s manufacturing environment. Our efficient production systems and responsive customer service ensure that you receive your orders on time, with clear communication throughout the process.

- Expertise and Industry Experience: With years of dedicated experience in the field, we have developed an deep understanding of the electrical industry’s needs. Our team of experts is capable of providing technical support and can even assist with custom requirements, ensuring you get the exact product you need.

- Customer-Centric Approach: Shalibhadra International, our relationship with clients doesn’t end with a sale. We pride ourselves on excellent customer service, timely delivery, and building long-term partnerships based on trust and mutual success. We are here to support your projects and ensure you have the right components for a safe and efficient electrical installation.

- Proven Industry Legacy: Our long-standing presence in the market is a testament to our reliability and the trust we have built with electrical contractors, panel builders, and large industries. We are a partner you can depend on for the long term.

- Rigorous Testing and Compliance: Safety is our core principle. Our products undergo a series of stringent quality checks and tests, including conductivity tests, thermal cycling tests, and dimensional inspections. We ensure our links meet and exceed relevant national and international safety standards, giving you the confidence that our products will perform when it matters most.

Applications of Brass Terminal Blocks

1. Industrial Control Panels

- In industrial settings, control panels are the backbone of electrical systems. Brass terminal blocks provide secure connections for wiring multiple components, ensuring smooth operations and reducing downtime caused by faulty connections.

2. Electrical Distribution Systems

- Terminal blocks are essential in electrical distribution boards, where they help organize and manage the wiring efficiently. Brass’s corrosion resistance ensures reliable performance even in high-moisture environments.

3. Automotive Industry

- Modern vehicles rely on intricate electrical systems for lighting, ignition, sensors, and more. Brass terminal blocks provide dependable connections that withstand vibration, temperature fluctuations, and mechanical stress.

4. Household Appliances

- From air conditioners to refrigerators, household appliances require safe and efficient electrical connections. Brass terminal blocks ensure these connections remain secure over the appliance’s lifetime.

5. Renewable Energy Systems

- In solar panels, wind turbines, and other renewable energy systems, reliable electrical connections are critical. Brass terminal blocks help maintain consistent power transmission and protect against environmental damage.

6. Communication Equipment

- Telecommunication systems and networking equipment demand precision and reliability. Brass terminal blocks facilitate secure connections, reducing signal loss and equipment downtime.

7. Machinery and Automation

- Automation equipment and industrial machinery often operate continuously under harsh conditions. Brass terminal blocks provide the durability and reliability required to maintain uninterrupted operations.

Table of Specifications Brass Terminal Blocks

| Specification | Description / Value |

|---|---|

| Material | Brass Terminal Blocks |

| Voltage Rating | 300V – 600V |

| Current Rating | 10A – 100A |

| Wire Size Range | 0.5 mm² – 16 mm² |

| Connection Type | Screw / Bolt / Spring |

| Operating Temperature | -40°C to 120°C |

| Insulation Resistance | >1000 MΩ |

| Color Options | Natural Brass / Nickel Plated |

| Standards Compliance | IEC, IS, UL (depending on model) |

| Application | Electrical panels, Industrial machinery, Automotive wiring, Renewable energy systems |

Advantages of Brass Terminal Blocks

- Excellent Electrical Conductivity Brass offers outstanding electrical conductivity, allowing for efficient current transfer between connected conductors with minimal power loss and reduced risk of overheating . While pure copper is slightly more conductive, brass provides the ideal balance between performance and practicality for most electrical applications.

- Superior Corrosion Resistance The zinc content in brass provides remarkable resistance to corrosion and tarnishing, ensuring reliable, long-lasting electrical connections even in moderately humid or challenging environments . This natural protection makes brass terminal blocks suitable for both indoor and outdoor applications where exposure to moisture might occur.

- Exceptional Mechanical Strength Brass is a robust and durable material, capable of withstanding the demands of industrial environments . Brass terminal blocks maintain high mechanical strength, enabling them to endure vibrations, shocks, and temperature fluctuations without compromising connection integrity . This durability means brass screw terminals can withstand repeated tightening and loosening without easily stripping or deforming.

- Cost-Effectiveness and Machinability Brass is relatively easy to machine into the complex shapes required for terminal components, making it a cost-effective solution for high-volume production of reliable electrical terminal blocks . This manufacturing efficiency, combined with its performance characteristics, positions brass as the optimal choice for projects balancing budget constraints with quality requirements .

- Enhanced Safety and Reliability Brass terminal blocks provide secure connections that prevent wires from loosening due to vibration or thermal cycling . This secure clamping minimizes the risk of short circuits, electrical fires, and equipment damage, ensuring operational safety in demanding environments.

- Simplified Maintenance and Installation The modular design of terminal blocks simplifies the process of wire insertion, connection, and securing . This ease of installation enhances efficiency and reduces downtime during maintenance or wiring modifications, providing significant cost savings over the system lifecycle.

- High Mechanical Strength: Brass is a strong and durable alloy. It can withstand the physical stress of being installed, with wires tightened into its terminals, without cracking or deforming. This mechanical robustness guarantees a long-lasting, vibration-proof connection.

- Remarkable Durability and Strength: Brass terminals can withstand high levels of mechanical and thermal stress without compromising performance . Their exceptional mechanical strength provides long-lasting durability that exceeds many alternative materials .

Types of Brass Terminal Blocks

1. Two-Pin Brass Terminal Block

- This type is the most commonly used terminal block. It connects two wires securely and is ideal for simple electrical circuits. Its compact size and ease of installation make it a popular choice in small electrical devices and control panels.

2. Multi-Pin Brass Terminal Block

- Multi-pin blocks allow multiple wire connections in a single unit. They are widely used in industrial control systems, machinery, and electrical panels where multiple connections are required.

3. Barrier Brass Terminal Block

- Barrier terminal blocks are designed to provide electrical insulation between connections. They are often used in industrial setups where electrical safety is critical.

4. DIN Rail Mounted Brass Terminal Block

- These blocks are designed for mounting on DIN rails, a common standard in industrial control panels. They allow quick installation, easy maintenance, and organized wiring.

5. Stud Type Brass Terminal Block

- Stud type terminal blocks use a screw or stud to secure the wire connection. They are robust and can handle higher current loads, making them ideal for heavy-duty electrical applications.

Conclusion

Brass terminal blocks are a vital component in modern electrical systems, offering reliability, safety, and efficiency. Whether for industrial machinery, automotive wiring, or home appliances, choosing high-quality terminal blocks ensures stable electrical connections and reduces maintenance costs.We are the Best Brass Terminal Block Manufacturers.

Shalibhadra International, a top manufacturer of brass terminal blocks, is distinguished by its superior quality, wide range of products, and customer-focused solutions. You can be sure that your electrical connections will be safe, effective, and long-lasting when you work with Shalibhadra International. Invest in dependability, quality, and longevity by selecting Shalibhadra International for all of your brass terminal block requirements.